Water jet-cutting machines have revolutionized the way industries cut and shape materials. In this article, we will delve into the basics of water jet cutting machines, how they work, and their advantages and limitations.

What is a Water Jet Cutting Machine?

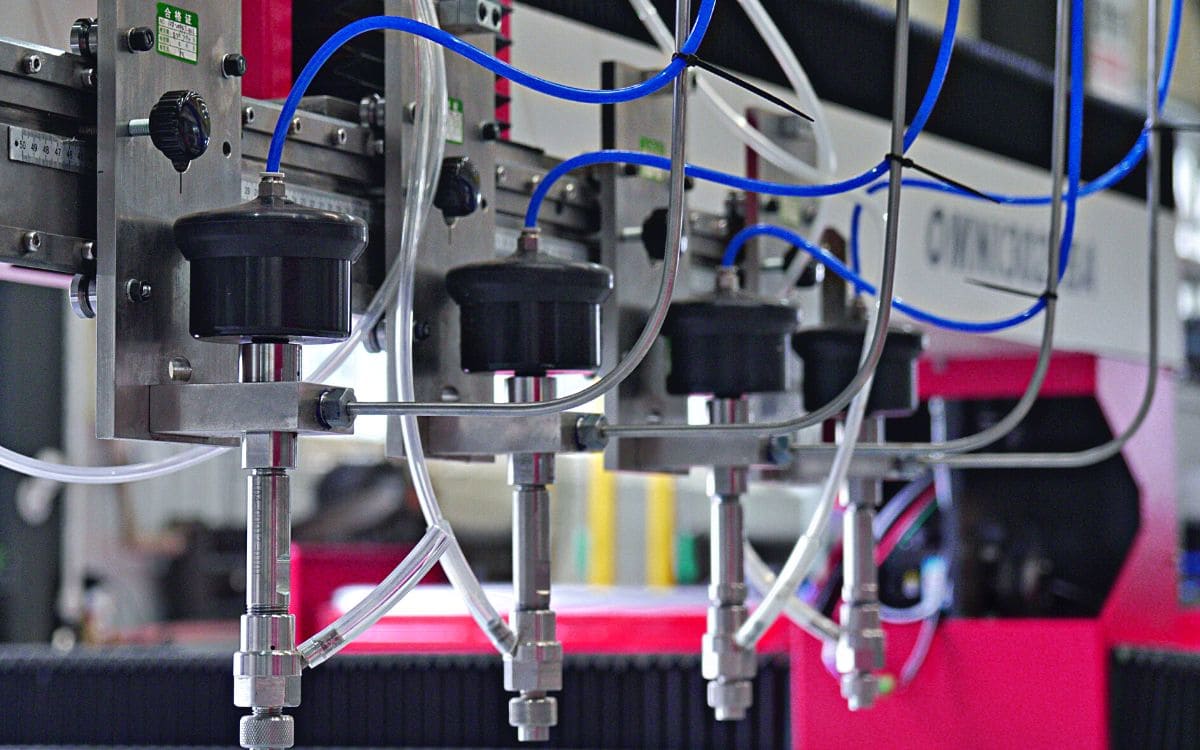

A water jet cutting machine is a tool that uses a high-pressure stream of water to cut through materials. The water is pressurized to an incredibly high level and then forced through a small orifice to create a narrow, high-velocity stream. OMNI CNC is a leading provider of advanced computer numerical control (CNC) systems for a wide variety of industrial applications. It offers products and systems that are designed to meet the demands of today’s ever-changing manufacturing landscape.

Advantages of Water Jet Cutting Machines

1. Precision: Water jet cutting machines can achieve high levels of precision, allowing for intricate and detailed cuts. This makes them suitable for industries that require exact measurements and fine cuts, such as aerospace and automotive.

2. Versatility: Water jet cutting machines can cut through a wide range of materials, including metal, stone, glass, and composites. This versatility makes them a preferred choice for industries that work with diverse materials.

3. No heat-affected zone: Traditional cutting methods, such as laser or plasma cutting, generate heat that can distort the material being cut. Water jet cutting, on the other hand, uses a cold-cutting process, which eliminates the heat-affected zone. This is particularly beneficial for materials that are sensitive to heat or prone to warping.

Conclusion

Water jet cutting machines have become a popular choice in various industries due to their precision, versatility, and environmental friendliness. With their ability to cut through a wide range of materials without heat or tool wear, they offer a flexible and efficient cutting solution. While they have some limitations, such as thickness and speed, the advantages outweigh the drawbacks for many applications.